Our Number 1 Service

Turbocharger Services

TurboPartsWorld offers the following Industrial Diesel Turbo-Charger repair services in addition to the replacement and manufacturing of industrial diesel turbo-charger parts:

TURBOCHARGER TEARDOWN, INSPECTION and DIAGNOSTIC EVALUATION

- Each GE, EMD, Alco turbocharger is carefully disassembled, chemically cleaned and closely inspected for wear, damage, tolerances, signs of metal fatigue as well as visual and functional anomalies.

- Observations on the GE, EMD, Alco turbocharger inspections are fully documented and reported to the customer along with a list, if known, of potential engine problems that could have been the source of any identified problems.

TURBOCHARGER CLEANING

- Turbocharger Turbines, compressors as well as all bearing housings are baked in our cleaning ovens at seven hundred degrees for six hours to remove carbon buildup, paint and other accumulated dirt both in and outside the turbocharger assemblies.

- The turbocharger assembly housings are then bead blasted, chemically washed and then treated for rust.

- Compressor housings are polished

- Turbocharger turbine assemblies and compressor wheels are bead blasted, chemically washed.

- Turbocharger shaft assemblies are chemically cleaned and measured with micrometers (“miked”) to ensure adequate tolerances are present.

TURBOCHARGER REPAIR

- Bearing housings are checked to conform to factory specs and repaired as needed

- Turbine housings are checked for cracks, wear and other damage or other anomalies then repaired or replaced as needed

- Both turbine and compressor wheels are checked for damage and conformity to factory specs and are repaired or replaced as needed.

- Turbocharger shafts are “miked” (measured with a micrometer) and visually inspected for wear, cracks, anomalies, warping and repaired or replaced as needed.

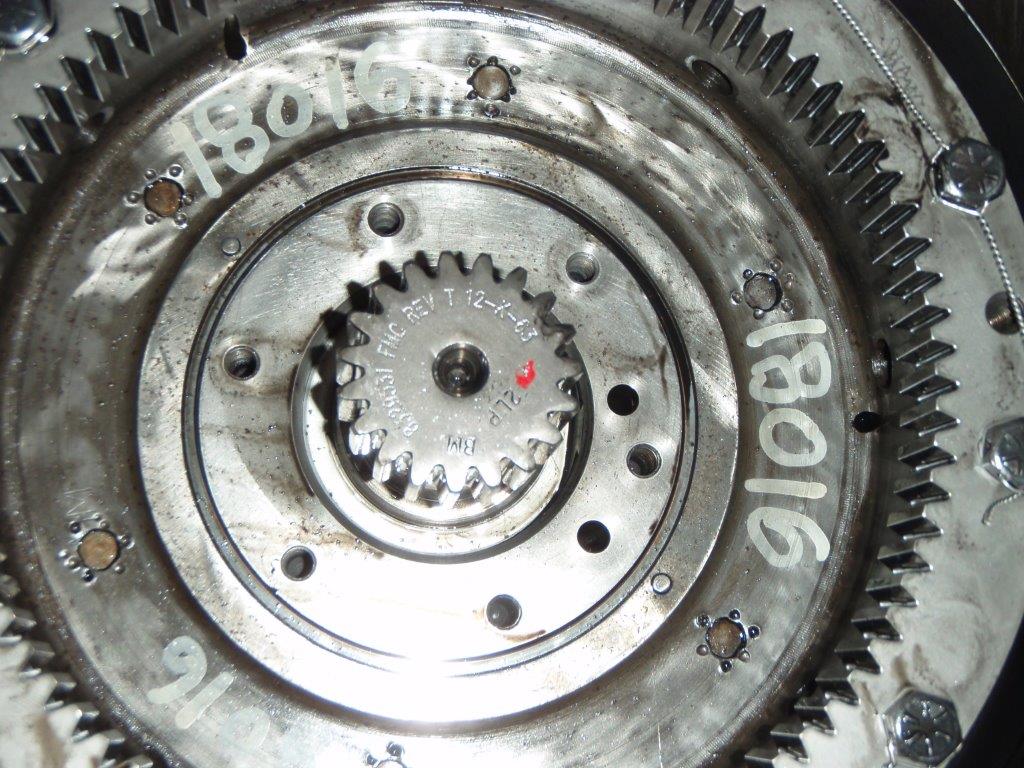

TURBOCHARGER BALANCING

- All Turbocharger and Rotor Assemblies, Turbocharger Turbine Assemblies and Turbocharger Compressor Wheels are balanced in all force planes appropriate to each device and machined to exceed the turbocharger’s original equipment manufacture (OEM) factory specifications.

TURBOCHARGER RE-ASSEMBLY

- Customers have the choice of Original Manufacturer Factory Parts (OEM GE, EMD, Alco ) when available, or top-tier aftermarket parts (We are very choosy and do not use sub-standard aftermarket parts) for any industrial diesel turbocharger rebuild or re-manufacturing project.

Constant quality-control checks are performed throughout the re-assembly process to ensure that all components and tolerances meet or exceed original factory (ALCO, EMD, GE. ELLIOT diesel turbochargers) specifications.

EMD Locomotive Parts

EMD Service Parts

We offer more solutions and new replacement original equipment manufacturer parts for locomotive, marine and power generation products than anyone in the industry. Comprehensive parts coverage is provided for all recent models, and parts are manufactured under sophisticated and exact quality control techniques. All EMD products are backed by a comprehensive warranty.

We employ a systems approach to product design, development, testing, manufacturing and packaging to ensure parts provide long-term dependable service. Our products are designed to meet the toughest applications, from extreme temperatures and altitudes, to heavy loading and load cycling. Advanced techniques, such as automated assembly and torque equipment, electronic profile and contour verification and daily metallurgical testing, are incorporated throughout the manufacturing process. And all EMD parts are carefully integrated in the overall product design to maximize efficiency and reliability.